TMR Stabilizer Pays for Itself

Aug 10, 2023

TMR Stabilizer can be used to prevent degradation in the feed bunk by stabilizing the pH in forages.

It contains 4 main acids that work synergistically to help control the stability of the feed. These include:

- Propionic Acid for control of molds

- Acetic Acid for control of bacteria and fungi

- Benzoic Acid for control of yeasts

- Sorbic Acid which is a slow release for control of mold long term

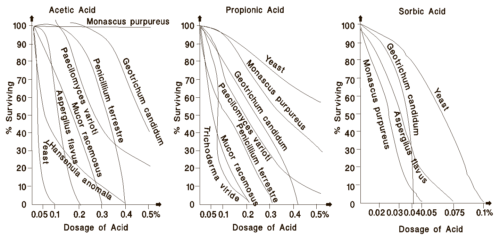

Graph shows which inorganic acids work best on yeast growth. Source: Pelhate J. (1973) Ann. Technol. Agric.22:647-661

We have also included 2 additional ingredients for added benefits:

- Ammonium Hydroxide which acts as a buffer making the product more user friendly and eliminates corrosion on equipment.

- Propylene Glycol which acts as a surfactant to aid acids in penetration of feedstuff particles allowing feedstuffs to be treated inside and out

Using this combination of ingredients, TMR stabilizer helps to protect the nutrition of your feed by preventing rancidity of fats, protecting against vitamin degradation, preventing off-flavors of feed, maintaining nutritional profile of feed, aiding in improvement of feed consumption (decreasing waste by about 2% where it is typically about 6-7% in warm conditions), and maintaining available energy levels of the feed mix which in turn helps with milk production.

TMR Stabilizer Pays for Itself

TMR Stabilizer comes in dry and liquid forms so typical cost of treatment is about 10-12 cents/cow/day.

Potential return:

- ¾ lb milk increase @ $0.18/# = $0.14 + 10 degrees

- 5 lb milk increase…………….. = $0.27 + 20 degrees

- 3 lb milk increase…………….. = $0.41 + 30 degrees

- 0 lb milk increase…………….. = $0.54 + 40 degrees

It takes LESS THAN ONE POUND OF MILK to pay for treated TMR!!

It is important to remember that the best method for control of yeast growth is at the bunker when storing feed, however TMR Stabilizer does provide a significant return on investment by controlling yeast and mold growth. This aids in extending the bunk life and preserving freshness of the feed resulting in consistency of palatability in the ration.

If you would like to learn more about adding UC TMR Stabilizer into your program, contact your UC Feed Sales Specialist today.