Reduce Corn Silage Shrink with Good Management

Jul 31, 2023

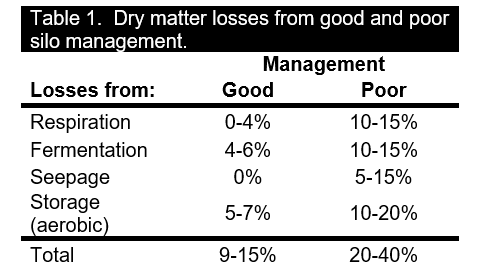

Inoculant use and good bunker covering can help improve Dry Matter loss by 10%, that’s $5.00/ton of value. See table 1 for how “Good Bunker Management” can really help improve losses in dry matter. It is important to pack silage well (densities of 16 lbs per cubic foot of dry matter or better), use a good quality inoculant and cover your silage properly where you minimize the amount of oxygen exposed to it. These good practices can keep you in the good range, where you only lose 8 to 10% to Dry Matter loss vs poor management that can be 20 – 40% Dry Matter loss!!

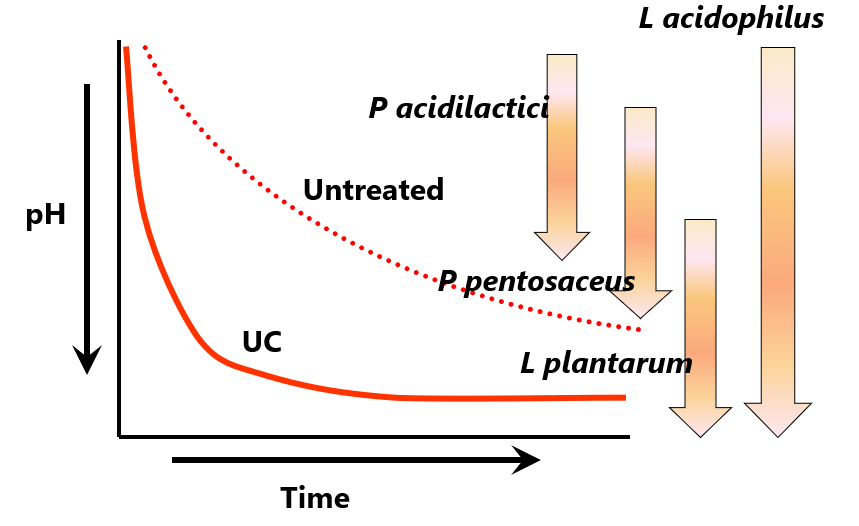

Silage inoculants are often misunderstood on what they do and how they do it. Silage fermentation is a war between the good bacteria and the bad bacteria (along with molds and yeasts). The goal of any forage producer is to make sure the “good guys” win. One way to do this is to control the front end of fermentation with overpowering the system with lactic acid-producing bacteria. These bacteria increase the amount of lactic acid produced and speed fermentation, which results in a faster drop in pH. This reduces protein degradation and allows for higher dry matter (yield) and energy recovery. Lactic acid-producing bacteria are a preservation tool for yield and quality, they are NOT a yield and quality enhancing tool (if garbage goes into the bunker, garbage will also come out). Our UC inoculant at United Cooperative carries 4 quality bacteria so that we have bacteria working at all times – some at higher pH’s and some at lower pH’s – see chart below. We have worked with a high-quality inoculant for over 15 years and have treated millions of tons of forage. Contact one of our Feed Specialist for more details or questions.

Finally, we need to cover our Corn Silage as soon as possible to minimize the amount of oxygen exposed to it. Also, weigh the cover down – best is tire-to-tire coverage – we don’t want oxygen to have a chance to be exposed to the forage mass until we are ready to feed it. If we have an air pocket or exposure to oxygen, we increase spoilage. When covering bunkers, I suggest a 2-layer covering system. The 1st layer to be a thin (1.5 to 2 mil thickness) underlay film that can suck tight to the forage surface and “cling” in a way that the thicker plastic can’t because it is less pliable, and that seems to help prevent oxygen from going underneath it. The 2nd layer of plastic (usually 5 mil or thicker) is our protection layer. Also, have covers securely weighted down so no air can “pump” under the plastic covering. Good luck with covering and be safe – it is the dreaded last thing to do.

In summary, be sure to pay attention to all details in harvesting and storing corn silage – doing so can help reduce shrink and preserve quality. Good milk production and increased animal production, starts with “high quality” forages. At United Cooperative we carry a full line of inoculants and Plastic products (silage bags, bunker covers and Silage shield covers) contact us for more details. Have a safe harvest.